Chemical Free & Filter Free Sterilisation

“ Aerolyz destroys microorganisms such as virus,bacteria, fungus, mould, and odour causing organic matter ”

Why Sterilisation ?

Case Study: Hospital

Hospital Acquired Infections (HAIs) are among the most common complications of hospital care, leading to high morbidity and mortality. While WHO estimates about 7-12% HAI burden in hospitalized patients globally, with more than 1.4 million people suffering from infectious complications acquired in the hospital at any time.

COVID-19 vulnerability: the potential impact of genetic susceptibility and airborne transmission The routes of exposure that have led to this high transmissivity have been the subject of considerable discussion, notably the contribution of aerosol transmission.

At office, conference room, healthcare facilities, airports and commercial airplanes we review several real-world settings with known difficulties controlling the airborne transmission of infectious particles, while detailing the respective measures each of these industries is undertaking in its effort to ameliorate the transmission of airborne infectious diseases.

Two main mode of getting HAI is through contact and/or through airborne germs. The infection through contact can be controlled by proper housekeeping and good hand hygiene practices. The airborne microbes are difficult to control because it needs poisonous chemicals to kill microbes and the room need to be isolated during fumigation, the typical cleaning process or use HEPA filters.

Desgned to work 24/7 for

• Intensive care units, Operations theaters , Isolation wards / rooms

• Air conditioned IT centers, Conference rooms, Data centers

• Hotels, Airports, Aero planes

• Doctor consultation rooms, Sterilized isolation room at homes for covid patients

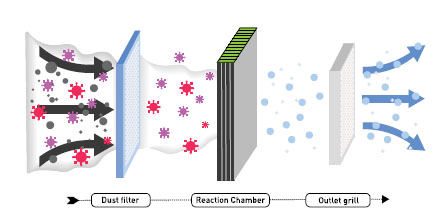

Common mode of Sterilisation

Using chemicals Poisonous and/or harsh chemicals are required for Steriliseing the rooms. Therefore,rooms cannot be used during the Sterilisation procedure (patients need to be vacated). After the prescribed time of Sterilisation, the excess chemicals need to be purged out of the room. Thus, all the excess chemicals for the Sterilisationis released into the environment, some of which are even carcinogen. One handicap of this method is that when the patient returns to the room, the microbe count goes up which mean the microbe count will be cyclical.

HEPA Filters are used widely by the hospitals to Sterilise the rooms. These filters canonly filter out germs/microbes larger than 0.3 microns. Although the germs areremoved they remain alive and multiply on the filter. As they are alive there is a possibility of recontaminating the area. Yet another challenge is the maintenance of the filter because there is no way to determine when the filter is full or need change. In addition to that changing the HEPA filter (every two years or when a highly infectious patient was in the room) is an expensive proposition.

UVCUVC can also be used to Sterilise the air, but there are two handicaps:

a) Carcinogenicity of UVC

b) Limited working radius of UVC

UV lamps should not be used to sterilize hands or other areas of skin as UV radiation. can cause skin irritation. Learn more on the World Health Organization website

Common Air Purifier Technologies

- HEPA filter: Can remove germs and dust larger than 0.3 microns (germs remain alive inside the filter).

- Activated carbon: Can remove odor but has limited capacity.

- Negative ion: Produces charged dust particles that settles faster.

- Ozone: Under certain conditions, it can react with organic mat- ter including germs.

- UV-C: Excellent at killing germs that are very close to the lamp; highly carcinogenic in nature; may produce ozone, a toxic gas.

Although the equipment works reasonably well for the consumer market, unfortunately, the efficiency of sterilisation and deodorization is below the level expected. The current technologies that dominate the professional market are HEPA filter and Upper-room UV-C. Due to the high initial investment and difficult, costly maintenance of these technologies, most of the organisations cannot afford . Deodorization is yet another challenge, which at present dealt by venting the air. This procedure is associated with high energy cost for the air-condition.

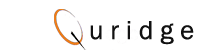

HOW OUR TECHNOLOGY WORKS?

The air in your space is Incessantly circulated through a catalytic reaction chamber, which immediately activates the photocatalysis that completely eradicates mould, fungi, odour and microorganisms like virus and bacteria in a fraction of second 0.16 secs. The photocatalyst is equipped by the unique and amazing excellent photocatalysis technology LECO or (LowEnergy Cascade Oxidation)

- Generate Valance B and Holes (VBH) in photocatalyst using light as energy source.

- Generate Hydroxy radicals (second highest oxidation power known in Chemistry) at the VBH.

- Oxidise organic compounds (including Microbes and VOC) in the air.

AEROLYZ sterilisation and deodorization equipment was developed by striking an optimum balance of the following factors:

1. Non-toxic components

2. Catalyst activation with low energy light

3. Long life for the energy source

4. High turbulence inside the catalyst chamber

5. Low noise

6. High disinfection and deodorization efficiency

The final equipment has a pre-filter (to protect the lamp and the catalyst from dust), fan to get the contaminated air into the equipment and a sterilisation /deodorization chamber. The sterilisation/deodorization chamber, the heart of the equipment simultaneously removes both microbes and volatile organic compounds efficiently from air in a single pass by oxidizing them – they are destroyed not filtered out. The equipment can be wall mounted, roof mounted or protable. This equipment need to be installed in any closed rooms with forced air circulation.

Another advantage of this equipment is the deodorization capability. The current equipment on the market use activated carbon technology for deodorization. Our unique equipment destroys/oxidises the organic, odorous molecules instead of storing it. This feature allows an unlimited capacity to remove the odorous molecules.

The main features of the equipment:

1. Chemical free air sterilisation (100%)

2. Chemical free deodorization (close to 100%)

3. Does not produce ozone.

4. Fastest kill rate globally 99.9999%.

5. Removes complete pathogen and odour - causing organic molecules by oxidising them.

6. Self-regenerating catalyst - No cartridge replacement required so no recurring cost.

7. 24 / 7 sterilisation without any interruptions

8. Minimal power consumption (50W for 600 Sq. Ft. room)

9. Ensures Sterilisation in just single pass in 0.15 seconds.

10. Noise level non-detectable less than 50db

11. Rugged design with intrinsic safety.

12 Capacity tailored to the room size and occupancy

Certificates and Standards

Rajiv Gandhi Centre for Biotechnology (RGCB) Certifies Aerolyzr Air Sterilizer

‘100 per-cent safe bet against Coronavirus pathogen’

In a path-breaking fight against Covid-19, Rajiv Gandhi Centre for Biotechnology (RGCB), the national autonomous institute under the Department of Biotechnology, has certified Aerolyz, the patented air sterilizer operating in visible light photo-catalytic technology as 100 per cent safe air treatment sterilization technology for air-conditioned, closed environments.

The certificate, issued by the RGCB states that the tests were performed using the single-pass method according to a modified ISO protocol.To test the efficacy of the product Influenza A, 2009 H1N1-Swine flu, Coronavirus E gene and Coronavirus S gene were fed to the inlet of the sterilizer (AEROLYZ ASR 600) and subsequent air samples of different time intervals were checked for the presence of the pathogen using RT-PCR, endorses RGCB.

"Tests were carried with more than 100 million virus count per milliliter in four-time intervals, in total 80 times and it is concluded that AEROLYZ ASR 600 Air sterilizer is efficient enough to eradicate 100 per cent of Influenza A, 2009 H1N1-Swine flu, Coronavirus E gene, and Coronavirus S gene in a single pass through the equipment," the RGCB certification confirms.

The low energy cascade oxidation technology in Aerolyz makes use of harmless visible light to activate the nano-coated catalyst to vaporize pathogens in the air without emitting any harmful byproducts.

The technology, instead of filtering and storing harmful germs, kills the entire micro-organisms in the air, thereby ensuring a germs-free, healthy environment in any closed, air conditioned ambiances like auditoriums, offices, hospitals, and business spaces.

AEROLYZ ASR: Standalone plug & play models

| ASR-300 | ASR-600 | ||

| Application Space | Sq. Ft | 300 | 600 |

| Voltage | V | 220-240 | 220-240 |

| Power Consumption | W | 35 | 50 |

| Net Weight | Kg | 10.5 | 13 |

| Dimension | LxBxH (mm) | 880 * 277 * 10 | 880 * 277 * 13 |

| Air Flow | m3/h (cfm) | 65 | 120 |

| Noise | dB | <55 | <55 |

| Air Filter (reusable) | micron | 2 | 2 |

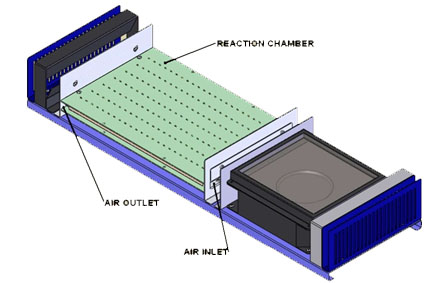

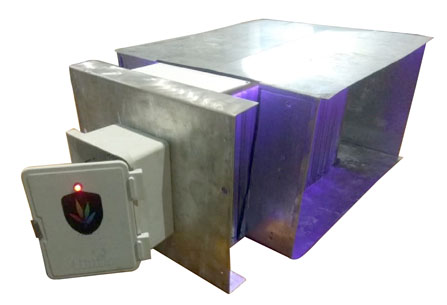

AEROLYZ HVAS: Project solution for existing air condition duct

AEROLYZ HVAS is a custom product made to match the customer existing air condition duct. We provide a reaction chamber which can be directly placed into the existing duct. The retrofitting can be done with much ease and without changing the structure of the existing duct.

For this solution we need to have system study of your current air condition system, AC duct etc. This solution is suitable for covering large area and might take longer implementation time compare to standalone units.